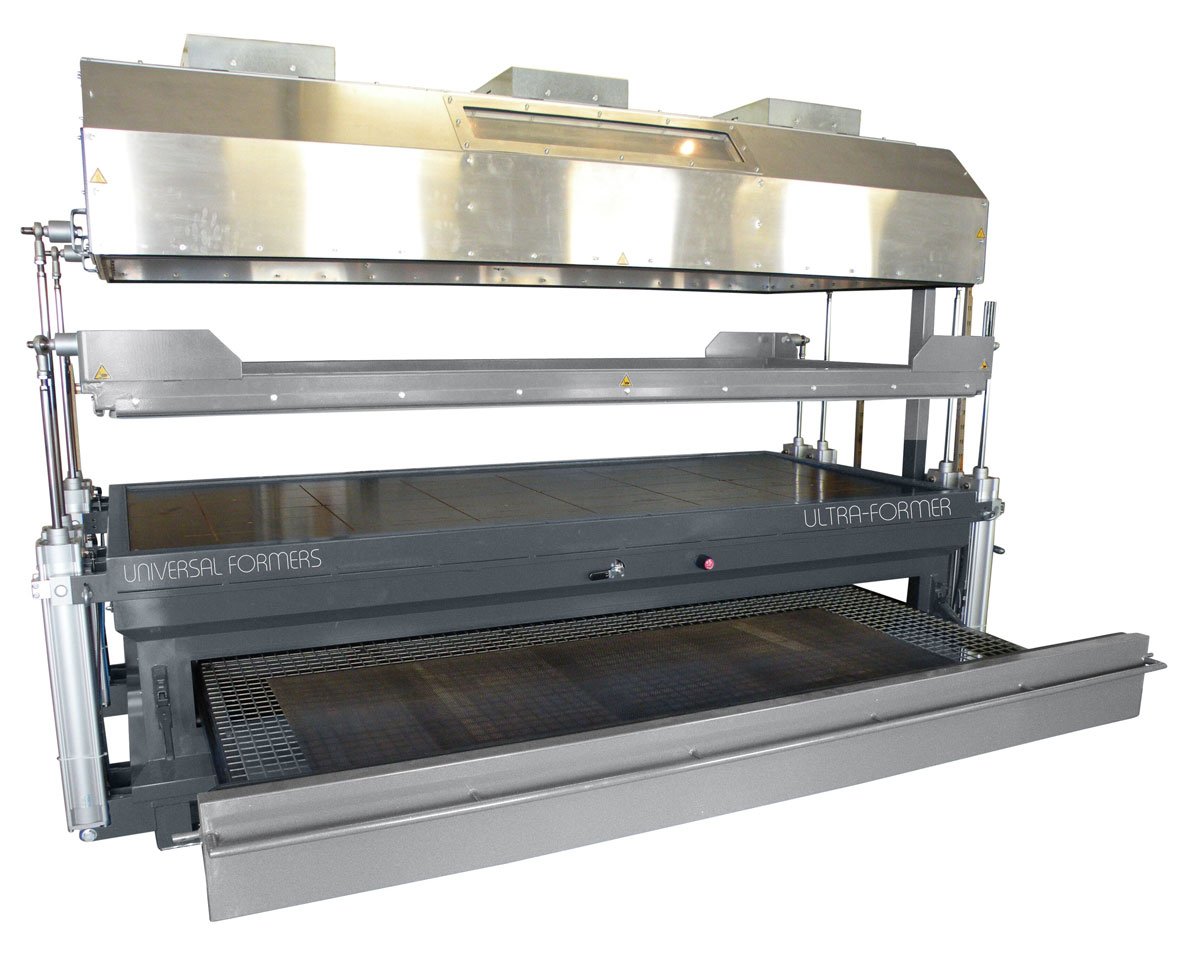

ULTRA-FORMER

The ultimate machine for precise heating and forming processes

‘TO FUTURE PROOF YOUR BUSINESS’

UTILISING A SIEMENS CONTROL UNIT THAT ENABLES THE ‘HEATED HOOD’ – ‘HEATED DRAWER’ AND ‘DEEP DRAWING FRAME’ PLUS THE ‘MEMBRANE FRAME’ TO ACCURATELY PERFORM TO YOUR SPECIFIC REQUIREMENTS IN CREATING EXCLUSIVE PRODUCTS THAT WILL ‘FUTURE PROOF YOUR BUSINESS’

What the ULTRA-FORMER can do for you

Foil laminating: With the heated hood – all foils + kydex + boltaron

Deep draw forming: For ‘one offs’ or multipals utilising the fully adjustable steel frames to ensure minimum material wastage and exceptional user control.

Thermoform: From the heated drawer – solid surface products (avonite – corian – himacs – hanex – kerrock – krion – meganite – staron – perspex – acrylic – polycarbonate – abs – pvc – pet – grada ply – etc.)

Vacuum press: All of the above plus ‘others’ as new products are always testing us to inform you, our customer, with the solutions.

Laminating & veneering: Either shapes or flat bonding – use the heated hood to speed adhesive ‘going off’

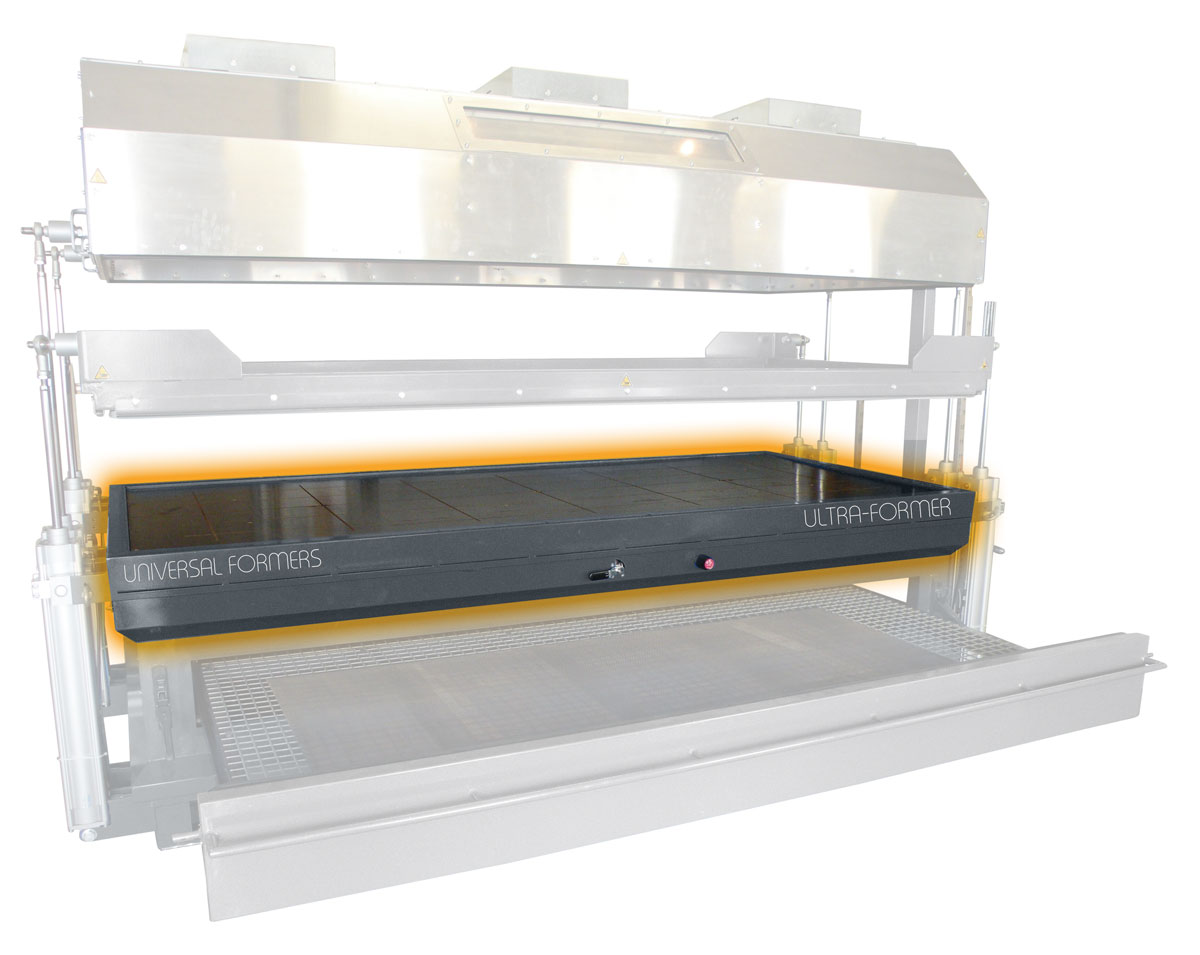

Pre-drying: Use the ‘heated drawer’ to pre dry those products that have a moisture content

ULTRA-FORMER -basic

3D Foil and Vacuum Pressing

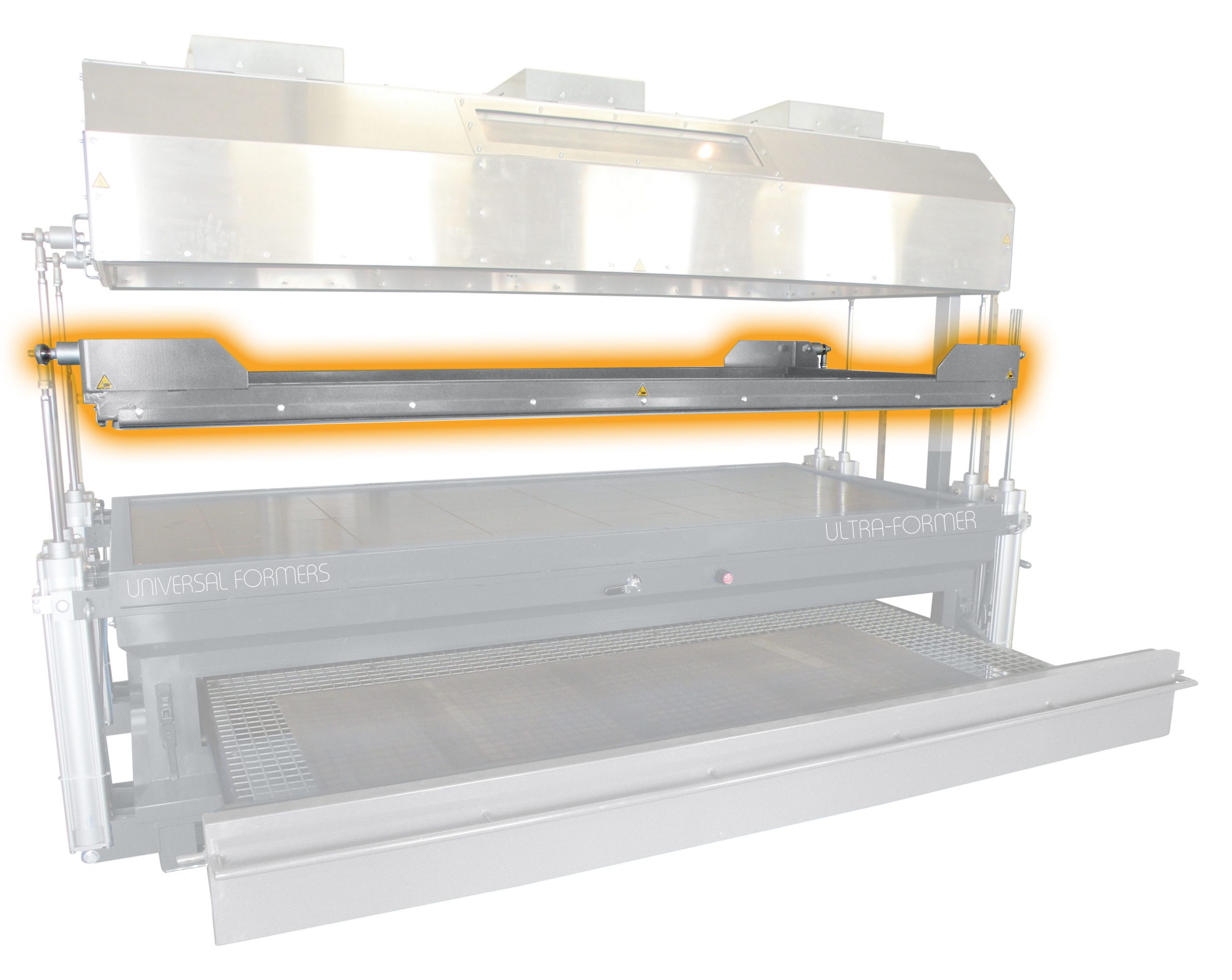

Vacuum table with independent CLAMSHELL opening of the membrane frame and heating hood with pneumatic cylinders

Vacuum table with independent VERTICAL opening of the membrane frame and heating hood with pneumatic cylinders, stroke 650 mm

Usable area: Approx. 2880 x 1280 mm | sunken working surface | compact solid core working surface with integrated air suction channels, heat resistant up to 160 °C | 40 m³ or 80m³ high-performance vacuum pump, pressure up to 900 mbar (9 t/m²) | mobile control cabinet on casters | mechanical vacuum pressure regulator | highly elastic silicone membrane up to 230 °C | membrane fast-change system | connector for external vacuum bag | swivel castors

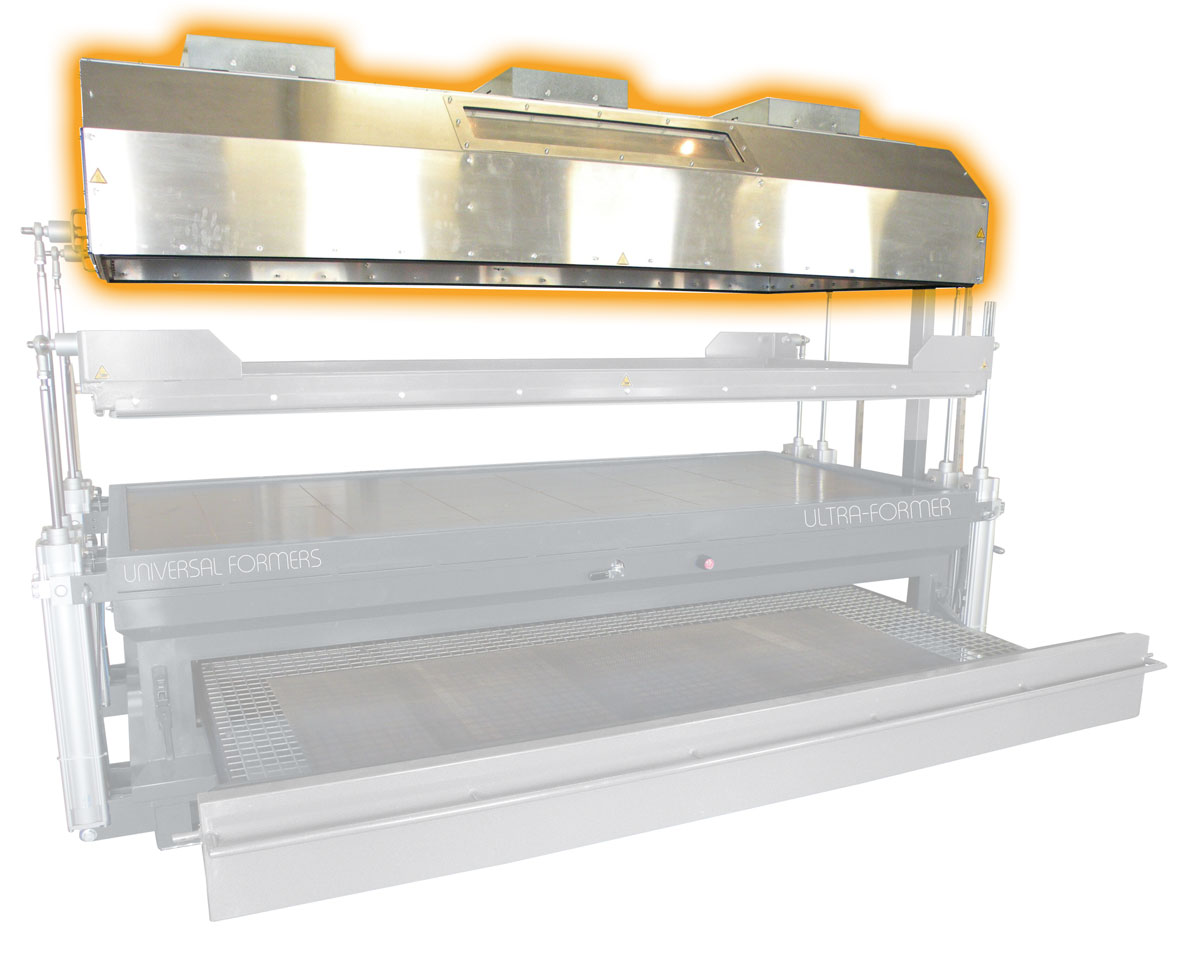

Industrial heating hood

Variable setting up to +210 °C | height inside 500mm | electronic temperature control | heating power: 13,5 kW, 32 Amp., 400 V, 50/60 Hz | 3 circulation hot air fans | fully insulated

Control

9“ Simatic HMI Touch Panel with two installed programs. | Forming program, fully automated process control for foiling and forming processes with the heating hood, adjustable parameters: heating time, pressing time, cooling time and venting time | Combination program, fully automated process control for specific heating processes with the heating hood, up to 10 process steps and variable setting of the parameters: temperature, heating time, cooling time. Storage of 99 heating processes. | manual and automatic mode

Optional

Deep drawing frame for 3D high parts foiling in adjustable sizes, only vertical model

Overall dimensions:

Clamshell approx. 4000 x 2000 x 1800 mm, height hood open 2000 mm

Vertical approx. 4000 x 2000 x 1800 mm, height hood open 2400 mm

ULTRA-FORMER – standard

Thermoforming + 3D foil + vacuum pressing

Vacuum table with independent CLAMSHELL opening of the membrane frame and heating hood with pneumatic cylinders

Vacuum table with independent VERTICAL opening of the membrane frame and heating hood with pneumatic cylinders, stroke 650 mm

Usable area: Approx. 2880 x 1280 mm | sunken working surface | compact solid core working surface with integrated air suction channels, heat resistant up to 160 °C | 40 m³ or 80m³ high-performance vacuum pump, pressure up to 900 mbar (9 t/m²) | mechanical vacuum pressure regulator

highly elastic silicone membrane up to 230 °C | membrane fast-change system | connector for external vacuum bag | mobile control cabinet on casters

Industrial heating hood

Variable setting up to +210 °C | height inside 500mm | electronic temperature control | heating power: 13,5 kW, 32 Amp., 400 V, 50/60 Hz | 3 circulation hot air fans | fully insulated

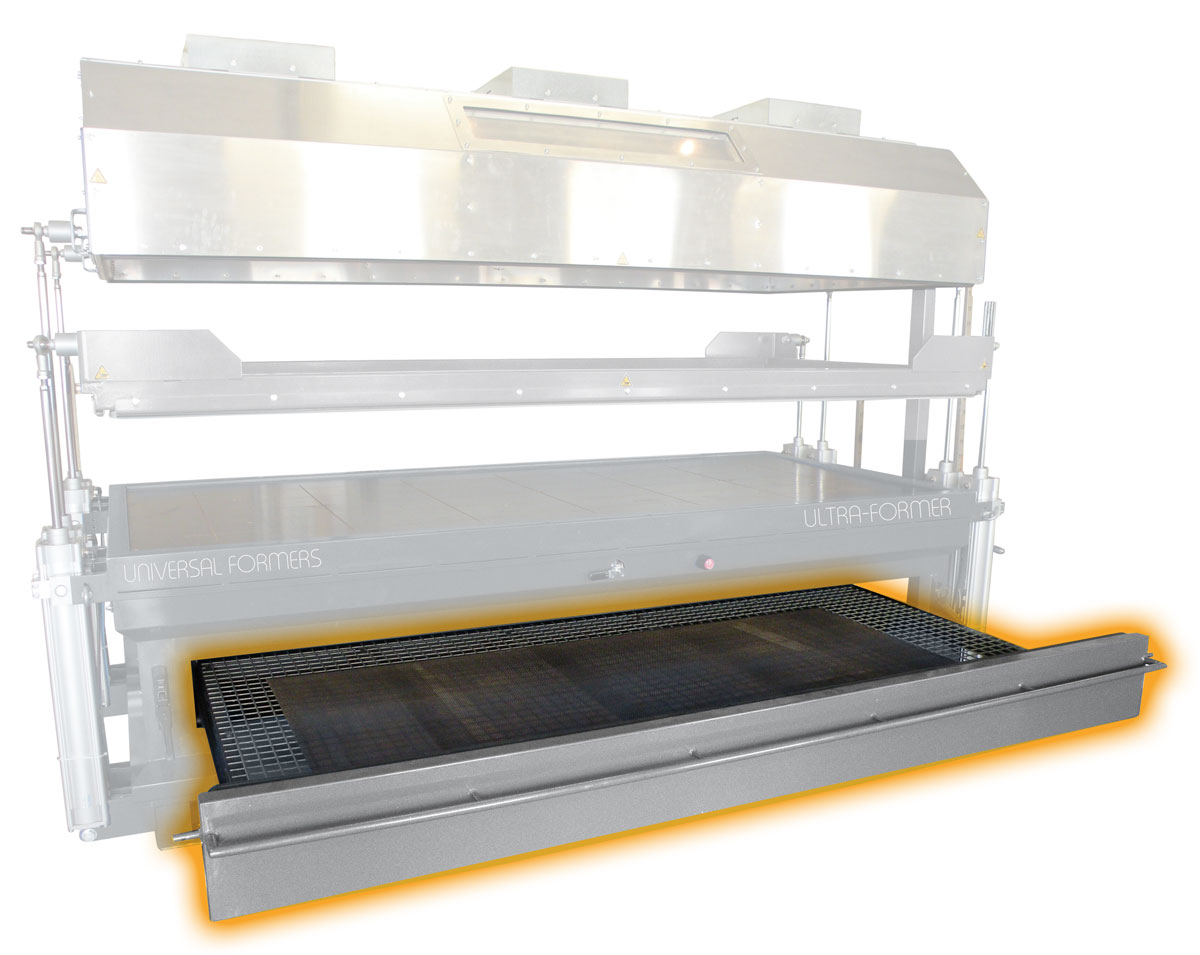

Heating drawer

Usable area: Approx. 2600 x 1200 mm, material thickness: 0 – 70 mm | pull-out working surface with grating, grid 30 x 30 mm | CAS heating system, heating power 16 kW, 400 V, 50/60 Hz, 2 circulating hot air fans | temperature control up to + 230 °C, heating time control, timer and alarm on main control panel

Control

9“ or 12” Simatic HMI Touch Panel with two installed programs. | Forming program, fully automated process control for foiling and forming processes with the heating hood, adjustable parameters: heating time, pressing time, cooling time and venting time | Combination program, fully automated process control for specific heating processes with the heating hood and heating drawer, up to 10 process steps and variable setting of the parameters: temperature, heating time, cooling time. Storage of 99 heating processes. | manual and automatic mode

Optional

Deep drawing frame for 3D high parts foiling in adjustable sizes, only vertical model

Overall dimensions:

Clamshell approx. 4000 x 2000 x 1800 mm, height hood open 2000 mm

Vertical approx. 4000 x 2000 x 1800 mm, height hood open 2400 mm

ULTRA-FORMER – mega

3D thermoforming + forming + 3D foil + vacuum pressing

Vacuum table with independent VERTICAL opening of the membrane frame and heating hood with pneumatic cylinders, stroke 650 mm

Usable area: approx. 2880 x 1280 mm | adjustable deep drawing frame with sub frames for thermoforming | sunken working surface | fine machined aluminium surface with 3 air outlets, heat resistant up to 250 °C | 40 m³ or 80m³ high-performance vacuum pump, pressure up to 900 mbar (9 t/m²) | mechanical vacuum pressure regulator | highly elastic silicone membrane up to 230 °C | membrane fast-change system | connector for external vacuum bag | mobile control cabinet on casters

Industrial heating hood

Variable setting up to +210 °C | height inside 500mm | electronic temperature control | heating power: 13,5 kW, 32 Amp., 400 V, 50/60 Hz | 3 circulation hot air fans | fully insulated

Heating drawer

Usable area: approx. 2600 x 1200 mm, material thickness: 0 – 70 mm | pull-out working surface with grating, grid 30 x 30 mm | CAS heating system, heating power 16 kW, 400 V, 50/60 Hz, 2 circulating hot air fans | temperature control up to + 230 °C, heating time control, timer and alarm on main control panel

Control

9“ or 12” Simatic HMI Touch Panel with two installed programs. | Forming program, fully automated process control for 3D thermoforming and foiling processes with the heating hood and deep drawing frame, adjustable parameters: heating time, pressing time, cooling time and venting time | Combination program, fully automated process control for specific heating processes with the heating hood and heating drawer, up to 10 process steps and variable setting of the parameters: temperature, heating time, cooling time. Storage of 99 heating processes. | manual and automatic mode

Overall dimensions:

Clamshell approx. 4000 x 2000 x 1800 mm, height hood open 2000 mm

Vertical approx. 4000 x 2000 x 1800 mm, height hood open 2400 mm

ULTRA-FORMER – mega l

3D thermoforming + forming + 3D foil + vacuum pressing

Vacuum table with independent VERTICAL opening of the membrane frame and heating hood with pneumatic cylinders, stroke 650 mm

Usable area: approx. 2880 x 1380 mm | adjustable deep drawing frame with sub frames for thermoforming | flat working surface | fine machined aluminium surface with 3 air outlets, heat resistant up to 250 °C | 40 m³ or 80m³ high-performance vacuum pump, pressure up to 900 mbar (9 t/m²) | mechanical vacuum pressure regulator | highly elastic silicone membrane up to 230 °C | membrane fast-change system | connector for external vacuum bag | mobile control cabinet on casters

Industrial heating hood

Variable setting up to +210 °C | height inside 500mm | electronic temperature control | heating power: 13,5 kW, 32 Amp., 400 V, 50/60 Hz | 3 circulation hot air fans | fully insulated

Heating drawer

Usable area: approx. 2600 x 1250 mm, material thickness: 0 – 70 mm | pull-out working surface with grating, grid 30 x 30 mm | CAS heating system, heating power 16 kW, 400 V, 50/60 Hz, 2 circulating hot air fans | temperature control up to + 230 °C, heating time control, timer and alarm on main control panel

Control

9“ or 12” Simatic HMI Touch Panel with two installed programs. | Forming program, fully automated process control for 3D thermoforming and foiling processes with the heating hood and deep drawing frame, adjustable parameters: heating time, pressing time, cooling time and venting time | Combination program, fully automated process control for specific heating processes with the heating hood and heating drawer, up to 10 process steps and variable setting of the parameters: temperature, heating time, cooling time. Storage of 99 heating processes. | manual and automatic mode

Overall dimensions:

Clamshell approx. 4000 x 2100 x 1800 mm, height hood open 2000 mm

Vertical approx. 4000 x 2100 x 1800 mm, height hood open 2400 mm

DON’T CALL US, WE’LL CALL YOU

Request a Callback

Fill in the form below to request a callback to discuss your bespoke needs.

LATEST NEWS

From Our Blog

CUSTOM MADE

This customer is making a mint!

ON TIME & WITHIN BUDGET!!

The Duo-Former was built within the price and time quoted, shipped and delivered ON TIME in spite of all the odds against this happening!!