TECHNICAL DATA

We can supply all spare parts for COLUMBUS machines manufactured up to 09-2020

We can supply cut to size SILICONE & RUBBER MEMBRANES

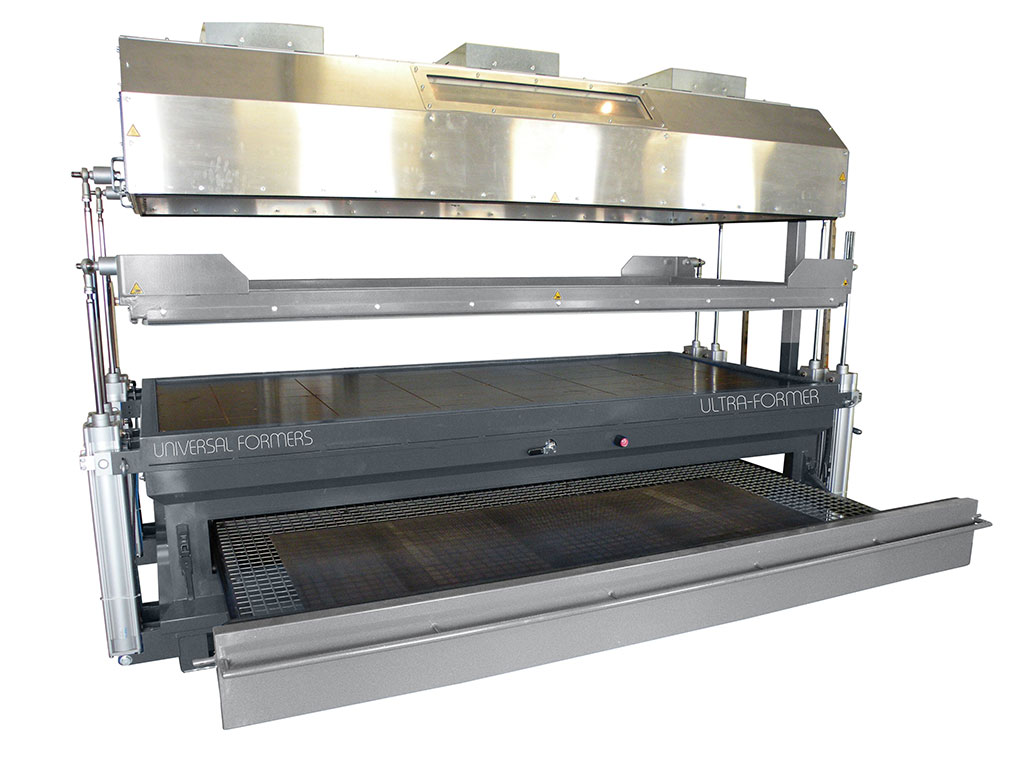

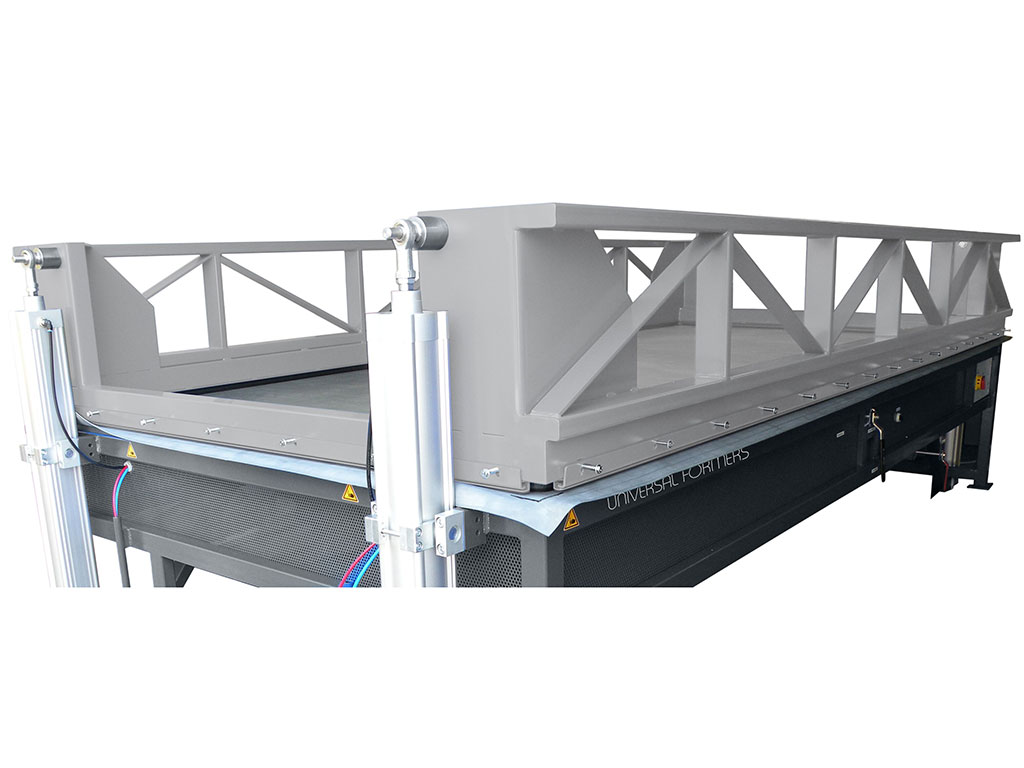

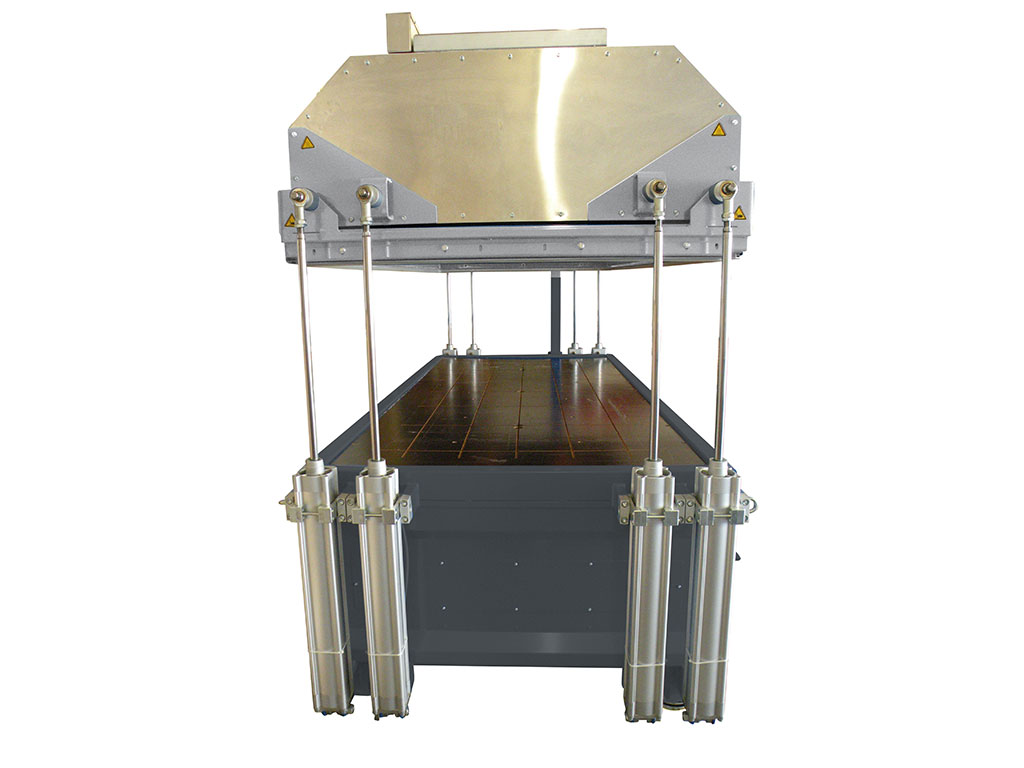

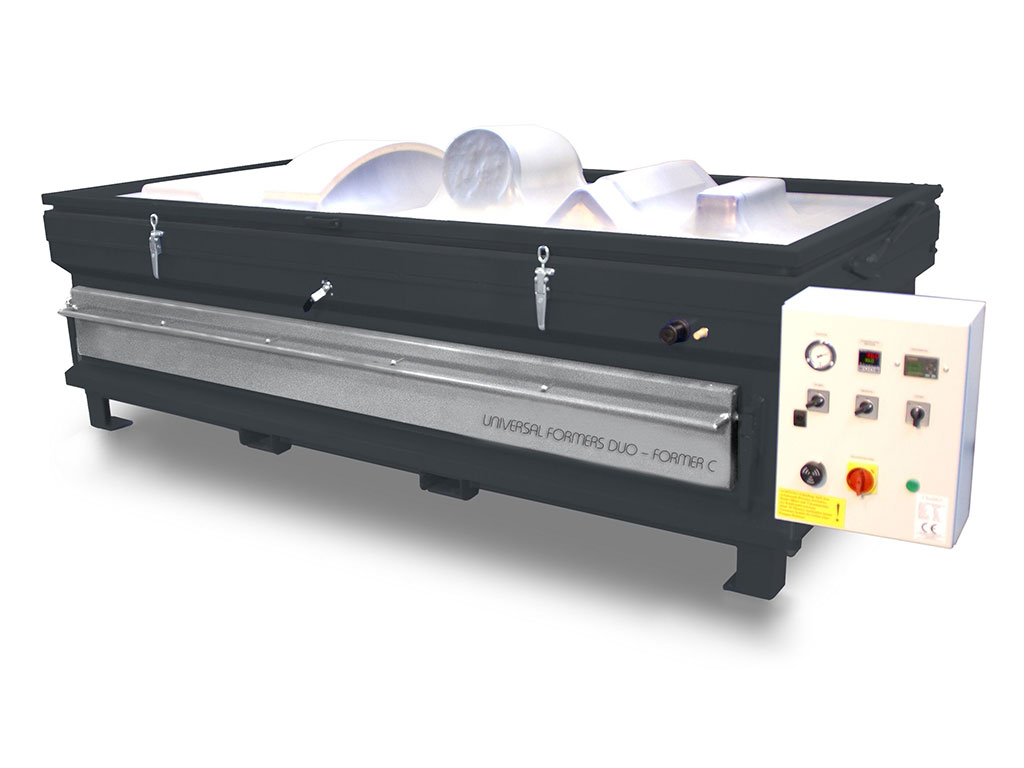

MACHINE CONSTRUCTION

Consists of a fully welded steel chassis that is torsion free to resist bending and twisting.

COMPACT / SOLID CORE LAMINATE WORK SURFACE

with air evacuation channels to quickly create a vacuum

ALUMINIUM WORK SURFACE

precision machined surface for all high temperature works up to 250°C

HEATING HOOD

Constructed of Aluminium sheet on aluminium frame with insulation

MEMBRANE FRAME

Quick change system enables different membranes, for different procedures, to be changed in approximately 10 minutes.

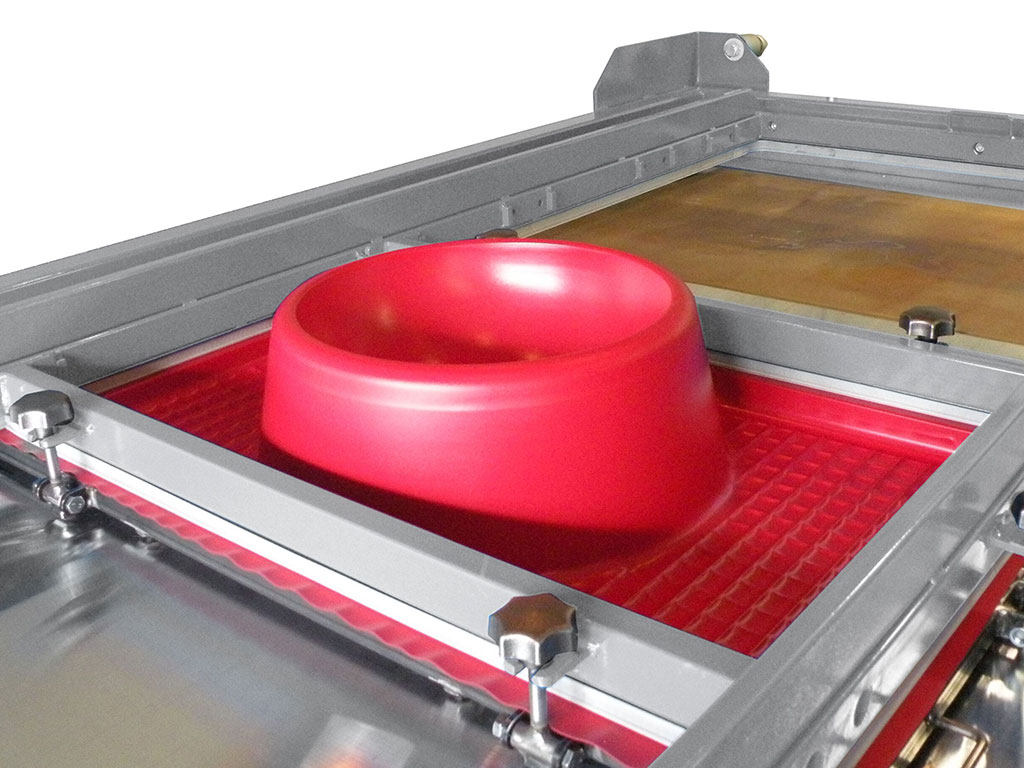

MEMBRANES

There are two options of membrane available for our machines, Silicone and Natural Rubber, they are interchangeable via our quick change system

DEEP DRAWING FRAME

A fully adjustable steel box frame to enable ‘one offs’ to be formed thereby using ‘just enough’ material to form your various finished products

VERTICAL OPERATION

The oil free pneumatic pistons rise & fall process enables precise placement of the ‘Heating Hood’ / ‘Deep Drawing Frame’ / ‘Membrane Frame’ over the work pieces whether they be shaped or flat – operated from the control unit using both hands for safety

HEATING DRAWER

One person operation easy roll out drawer with a 30mm x 30mm open steel grid to accept sheet products of 2550 x 1250 x 70mm or less (maximum size of the drawer)

VACUUM PUMPS

Universal Formers Pumps are BECKER rotary vane 100% oil free and maintenance free *(oil lubricated pumps can contaminate the work area, products and personnel with an ‘oil mist’) and benefit from very little servicing.

REMOTE CONTROL UNITS

Away from the heat & action, with SIEMENS touch panel (standard 9” extra 12”) enabling fully automated control of the ‘Heating Hood + ‘Deep Drawing Frame’ + ‘Membrane Frame’ + ‘Heating Drawer’ with manual override – the unit can be programmed with up to 99 saved individual manufacturing processes (999 on demand)

CONTROL UNIT

Control cabinet with SIEMENS touch panel for temperature control and heating time control for controlling the vacuum pump, the heating drawer and the travel movement of the membrane frame

CONTROL UNIT (CLAMSHELL)

Integrated control unit for controlling the vacuum pump

Vacuum control lever for vacuum generation and reduction

Pressure monitoring: analogue vacuum pressure gauge

CONTROL UNIT (VERTICAL)

SIEMENS Control cabinet with ‘pressing time’ & ‘vacuum pump’ & the travel movement of the membrane frame (vertical opening mechanism) capabilities

Manual Vacuum control lever for vacuum generation and reduction

Pressure monitoring: analogue vacuum pressure gauge

Updates: On demand with a vacuum tank, FESTO precise pressure control digital,

Extra programs: pressure and time in steps with SIEMENS touch panel

DON’T CALL US, WE’LL CALL YOU

Request a Callback

Fill in the form below to request a callback to discuss your bespoke needs.

LATEST NEWS

From Our Blog

CUSTOM MADE

This customer is making a mint!

ON TIME & WITHIN BUDGET!!

The Duo-Former was built within the price and time quoted, shipped and delivered ON TIME in spite of all the odds against this happening!!